Concrete Products

Bulk Commodities

Equipment

Pipelines and Fittings

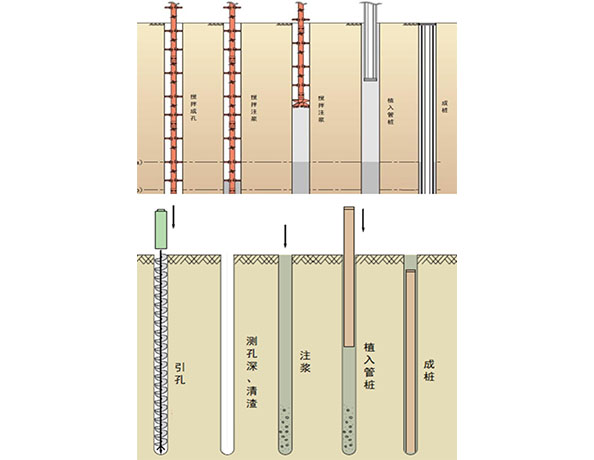

As a leading Precast Pile Manufacturer, Jianhua Holdings Group specializes in providing high-quality precast concrete piles designed for a wide range of construction and foundation applications. Our precast piles are engineered to deliver exceptional performance, durability, and cost-effectiveness for both commercial and industrial projects. Whether you're working on marine structures, bridges, highways, or residential buildings, our Precast Piles offer unmatched strength and reliability.

Designed to withstand substantial vertical and lateral loads, making them ideal for heavy infrastructure projects.

Resistant to corrosion, weathering, and environmental factors, ensuring longevity and reduced maintenance costs.

Pre-fabricated in controlled environments, Precast Piles are easy to transport and quickly installed on-site, minimizing construction delays.

Suitable for various applications, including bridges, docks, high-rise buildings, and foundation works in challenging soils or underwater environments.